Factory Digitalization with Real-Time IoT Dashboards

Project Overview

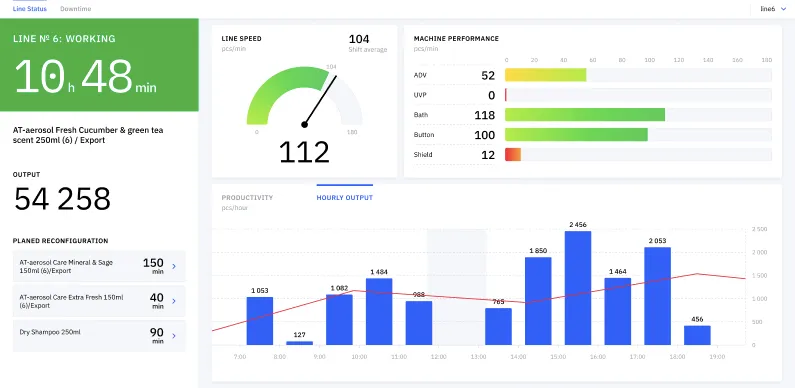

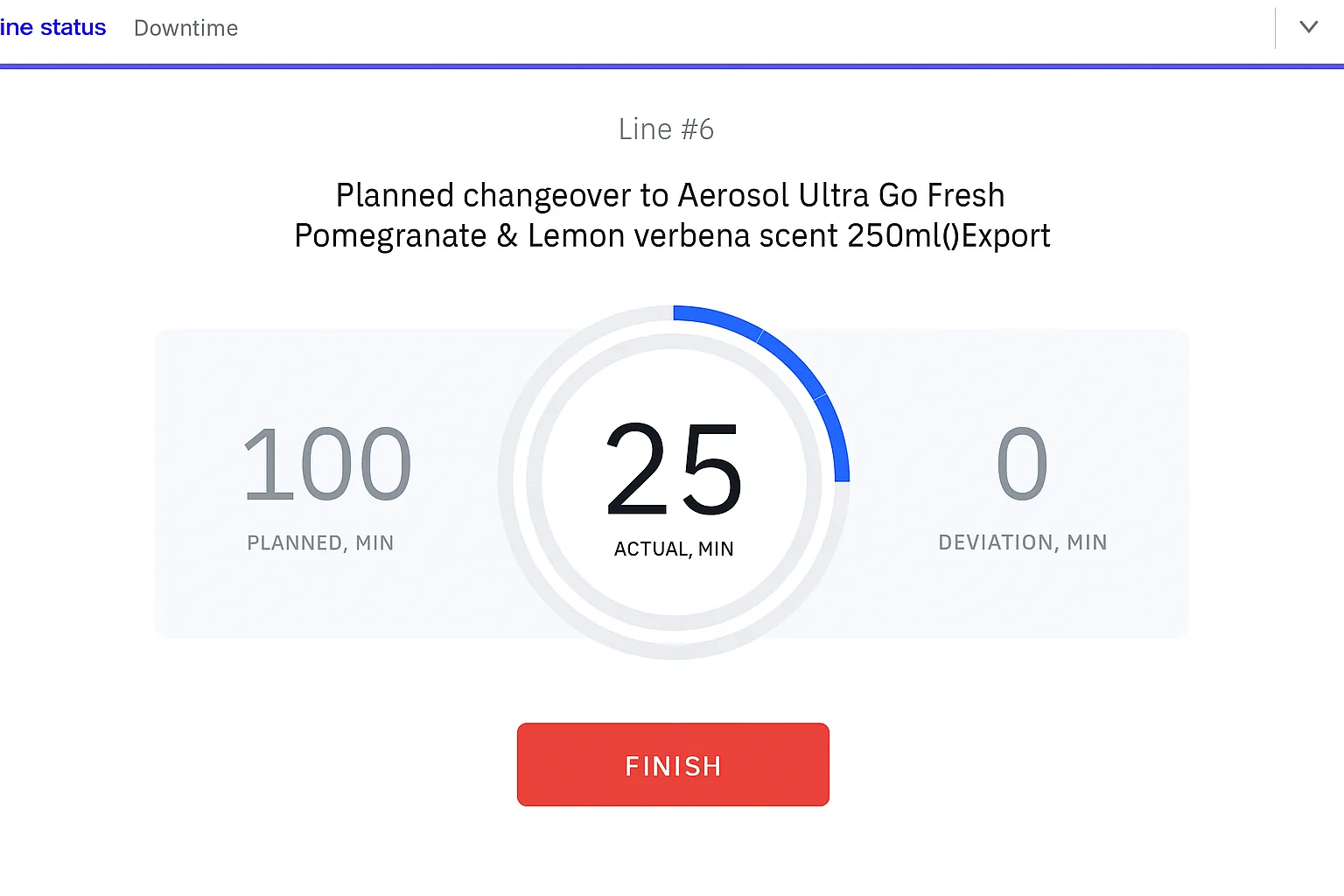

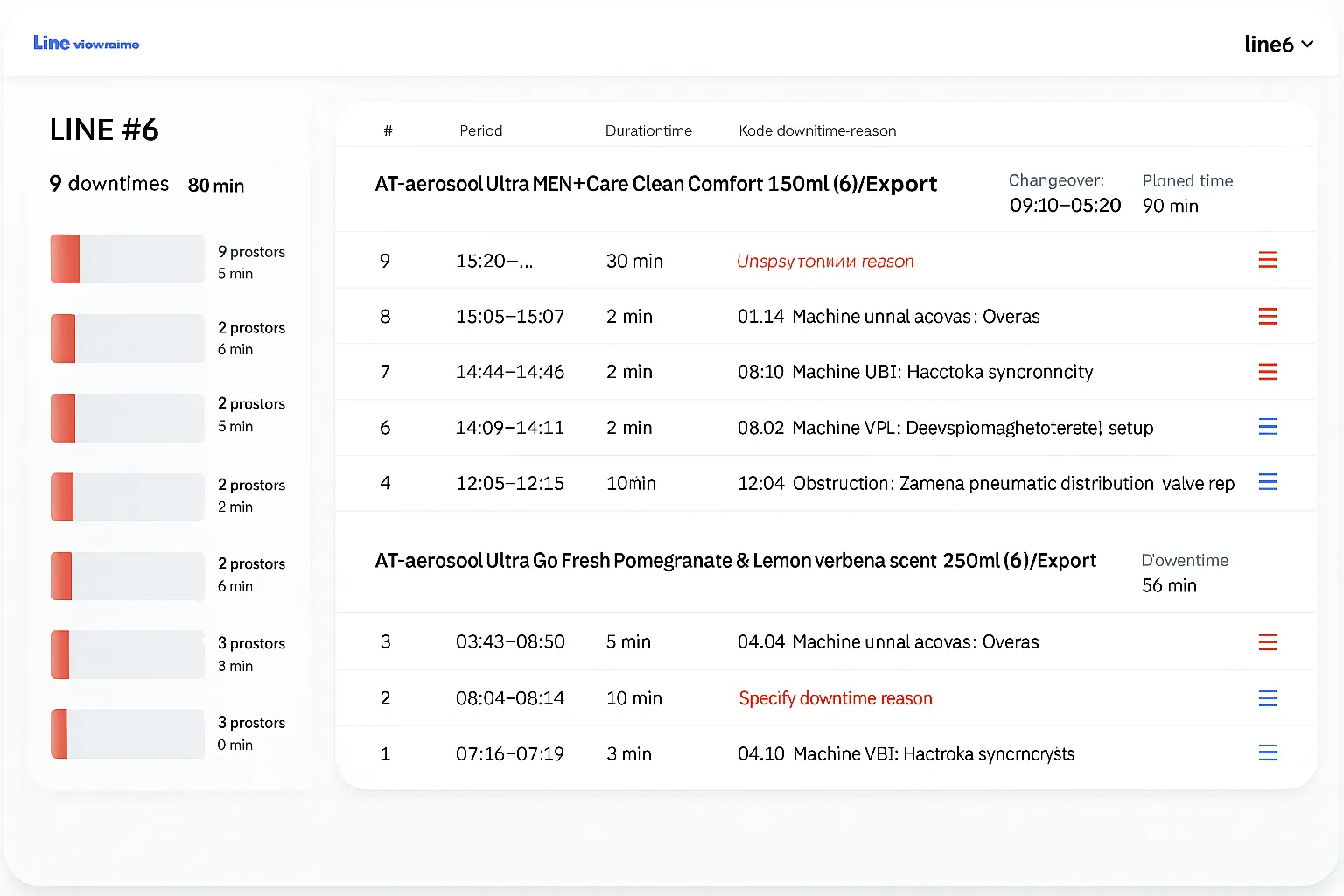

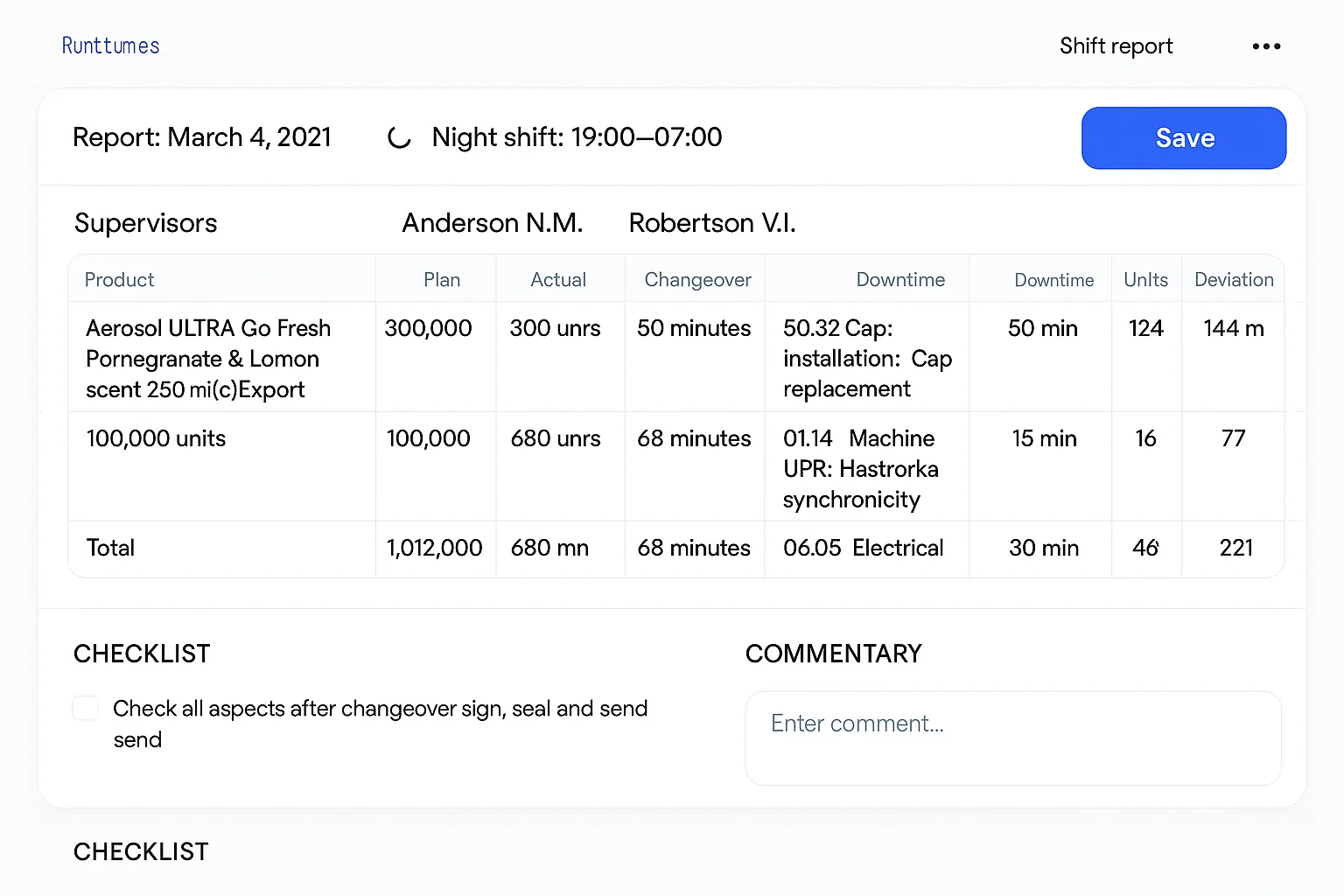

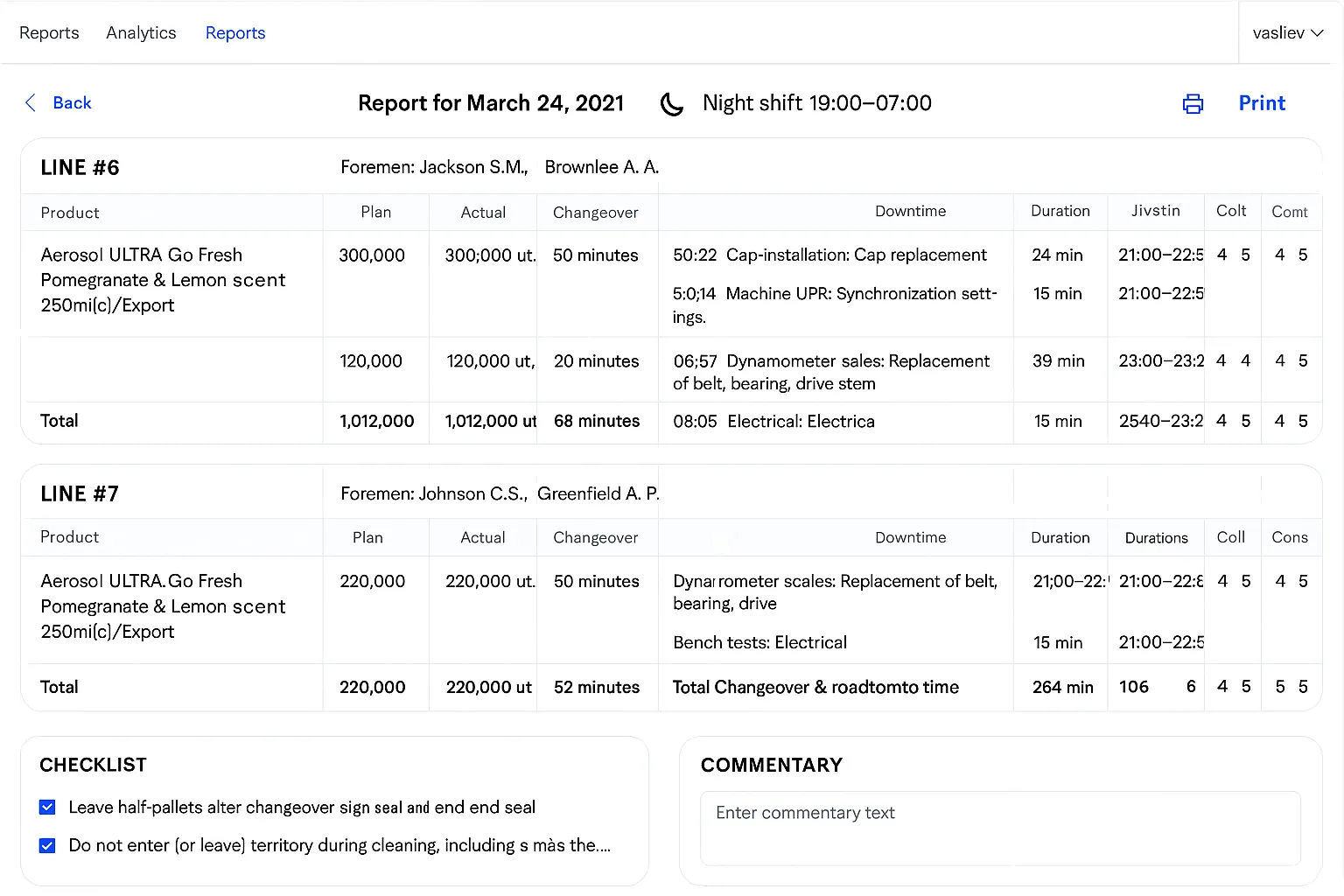

We are building a full-stack Industrial IoT platform that digitizes factory operations by turning each piece of shop-floor equipment into a real-time data source. Wireless sensors capture key parameters like temperature, speed, and downtime, streaming them to a cloud-native backend built with Python and modern JavaScript. The system replaces manual logs and spreadsheets with automated data collection, intuitive dashboards for operators, drill-down analytics for managers, and company-wide OEE tracking for executives. Key capabilities include real-time alerts, historical performance analysis, multi-shift reporting, and scheduled PDF/Excel exports. The platform is designed for scale, enabling deployment across multiple factories with minimal setup, significantly reducing manual work and enabling faster, data-driven decision-making at all levels of manufacturing.

Technology Stack

Application Showcase

Challenge

- Manual logs/spreadsheets prevent timely, accurate equipment telemetry; no unified, real-time view of machine states and downtime to compute OEE across shifts/sites.

- Shop-floor equipment isn’t instrumented for continuous streaming, so there are no early warnings for anomalies or emerging bottlenecks.

- Historical analysis and scheduled reporting are cumbersome without a single source of truth.

Our Solution

- Full-stack IIoT: wireless sensors emit real-time telemetry (temperature, speed, downtime) into a cloud-native backend built with Python + modern JavaScript.

- Role-based UIs: operator dashboards for live status, drill-down analytics for managers, and organization-wide OEE tracking for executives.

- Capabilities: real-time alerts, historical performance analysis, multi-shift reporting, and scheduled PDF/Excel exports.

- Built-for-scale deployment model enabling rapid rollout across multiple factories with minimal setup.

Results

- Manual logs replaced with automated data collection and unified dashboards across the plant.

- Faster, data-driven decisions and reduced manual effort via cloud analytics and OEE visibility.

- Improved operational discipline: proactive alerts and standardized, shift-level reporting backed by historical trends.